September 14, 2022

The Technical Situation

Industrial cameras are quantified by their sensitivity, linearity and uniformity.

Test and characterization of a camera’s sensor requires an extended uniform light source that irradiates the image sensor homogeneously without mounted lenses. The sensors are illuminated by a diffuse circular aperture light source with a specific diameter, placed in front of the camera sensor at a complementary distance from the sensor plane defined by the desired irradiance uniformity and f/#. Each pixel of the sensor must receive equal amounts of light or irradiance. For this application, the irradiance non-uniformity across the sensor active area shall be less than 3%.

The Challenges, and Labsphere’s Solution

The company produces machine vision cameras for OEM equipment suppliers to help them increase productivity of their inspection systems. Comprehensive and consistent specification information for their cameras and sensors is required to remain competitive in the automated vision industry.

The Results

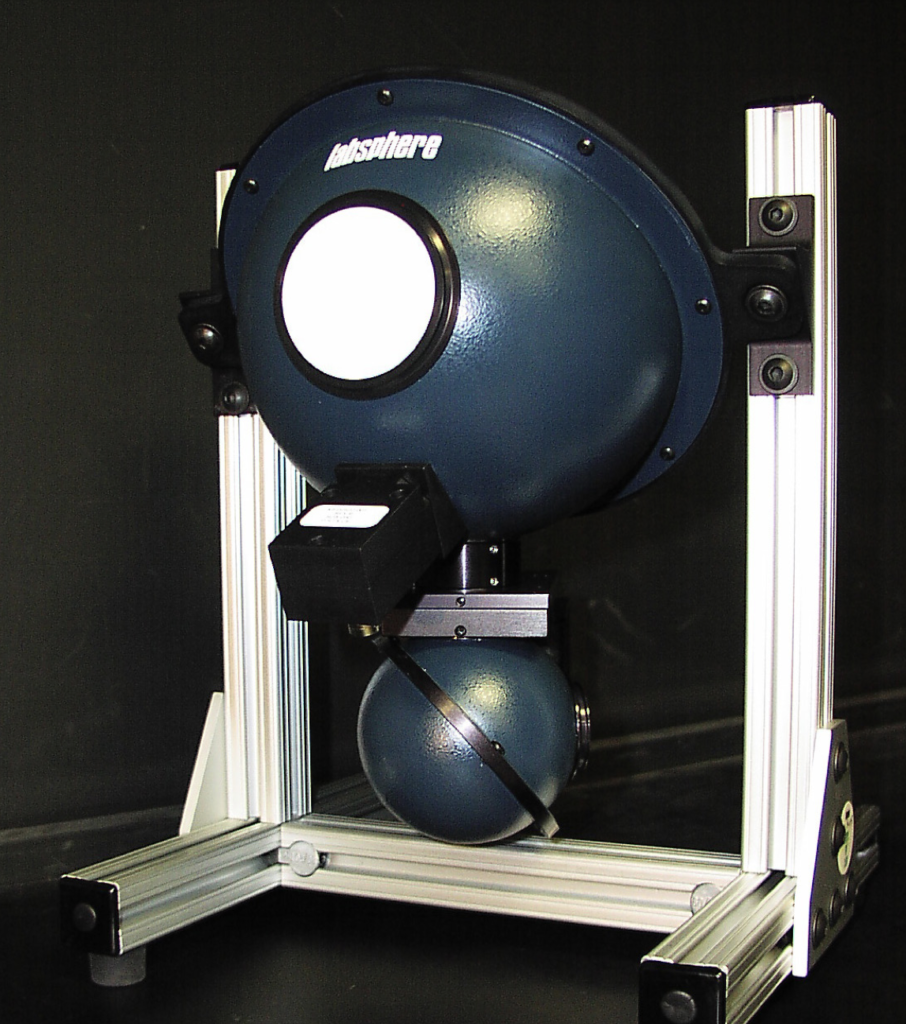

Labsphere’s small area integrating sphere uniform light source systems have a 5 cm port that provides 3000K of near blackbody spectrum with luminance uniformity greater than 98% at 2000 cd/m2. The high-quality systems use Labsphere designed LPS current regulated power supplies, programmable SC-6000 system control radiometer, and our programmable MC-1000 for variable radiance control that provides stable levels of known sphere spectral radiance and irradiance at the test plane.

| Objective | Benefits Achieved |

| A system that will provide uniform irradiance for camera sensor calibration | Labsphere’s uniform source systems provide high uniformity and user control |

| Knowing the irradiance on the sensor | Labsphere’s uniform source can monitor the irradiance on the sensor using the radiance sensor mounted on the sphere |

| Integrate with production test systems | Labsphere’s robust design and extruded frame makes it easy for integration and alignment |