January 6, 2022

By Russell Bailey, Product Manager, Pro-Lite Technology Ltd & Greg McKee, Chief Technologist & Product Marketing Manager, Labsphere, Inc.

LIDAR is an established technology that is being increasingly deployed in consumer products and in driverless vehicles. LIDAR is an acronym for Light Detection and Ranging. LIDAR systems have been used for over 50 years but until recently the costs for such systems have kept them from being viable in mass market applications.

Although Radar is a popular technology used in autonomous vehicle technologies, for example in adaptive cruise control systems, LIDAR is considered the sensor of choice in driver assisted cars when it comes to accuracy of mapping positions and distances, enabling detection of small objects and 3D imaging. It uses pulsed laser and solid-state light with time of flight sensing to measure distances. Characterization of LIDAR systems requires compensating the sensor response to the pulsed laser or solid-state light levels over a broad dynamic range of reflectance levels. This in turn requires the use of large area reflectance targets of known and stable reflectance. Labsphere’s Permaflect diffuse reflectance coated targets, ranging from 5% to 94% reflectance, enable automaker OEMS and their suppliers to characterise and calibrate their LIDAR systems over a broad range of environmental conditions.

The Technology of LIDAR

The most basic form of LIDAR is the laser rangefinder which has been widely used in military applications since the 1980s. Laser rangefinders consist of a pulsed laser (emitter) and a photodetector (receiver). The rangefinder is designed to allow for distances to be accurately measured (so-called “ranging”) and they rely upon measurement of the time taken for the laser pulse to be reflected and received back at the detector (this is referred to as a “time of flight” measurement).

The rangefinder is directed at a target and a laser pulse is emitted. The laser light strikes the target, is scattered and a proportion of the reflected light is measured by the detector. As the speed of light is very precisely known, the distance between the rangefinder and the target can be measured very accurately. More advanced LIDAR systems use the same principle but use optics and moving or multiple detectors to map targets in two dimensions. These systems typically pulse thousands of times a second, allowing for thousands of points to be detected each second. Analysing the data of this point cloud creates accurate maps of the target area. The way LIDAR works is analogous to Radar and Sonar, which use radio waves and sound waves, respectively. The data from Radar and Sonar can be used to map surroundings in a similar way, but LIDAR systems employ shorter wavelength infrared radiation compared to longer wavelength radio waves. As a consequence of the shorter wavelengths used, LIDAR measurements are more accurate than Radar.

LIDAR systems that are deployed on autonomous vehicles commonly use scanning laser beams and flash technologies to measure 3D points in space relative to the sensor. These LIDAR systems are typically emitting thousands of laser pulses per second so that the vehicle can react to obstacles such as pedestrians and other vehicles. LIDAR allows autonomous vehicles to deliver and receive reflected lighting of objects and the surrounding environment with high accuracy, resolution, and long detecting distances. More advanced AI (artificial intelligence) systems are being developed to predict vehicle and pedestrian paths and react accordingly. When you combine LIDAR data with positioning information (using GPS or similar) you can comprehensively map vehicle surroundings.

LIDAR performance is strongly dependent upon the laser power and wavelength being used. For safety reasons there is an upper limit to the amount of laser power that can be used. In the absence of ever higher laser powers, you can use a higher sensitivity detector or use a laser whose wavelength extends further into the infrared (IR). Due to the technological maturity of the available lasers, the wavelengths commonly used are 850nm, 905nm, or 1550nm. 1550nm lasers are safer than the other options because above 1400nm IR radiation is no longer transmitted through the cornea of the eye and so is not focused onto the retina but require more power to compensate for much higher water absorption at 1550 nm.

LIDAR in Consumer Electronics Products and in Autonomous Vehicles

LIDAR is a key enabling technology together with camera systems and other sensors in automation applications. LIDAR systems have been used commercially for many years in specialised mapping and related applications. However, it is only in recent years that LIDAR is becoming more commonplace, driven mainly by the need for smaller and cheaper devices in autonomous automotive applications (driverless cars). LIDAR has been used in semi-autonomous vehicles as the basis for adaptive cruise control since the early 1990s, while the first demonstration of LIDAR in an autonomous vehicle was in 2005.

In the field of consumer electronics, the latest generation of Apple’s iPad Pro (and now the iPhone 12 Pro) has integrated a LIDAR sensor into its camera array specifically for imaging and augmented reality (AR) applications. The LIDAR sensor allows the iPad to correctly interpret the position of real objects with respect to an AR object as imaged by the camera array. AR is in its infancy so it remains to be seen how relevant LIDAR is on smart phones and other consumer devices, but there is a great deal of interest in AR being developed for professional applications where LIDAR can be a very useful enhancement. The applications for professional AR are diverse, from assisting warehouse workers to navigate the fastest and safest route to the required part to engineers having an overlay of the process for a complex repair. LIDAR in these applications would allow for accurate positioning and alignment, which for any application requiring precision is important.

The Role of Diffuse Reflectance Targets in Testing and Calibrating LIDAR Systems

Pro-Lite and Labsphere have been supporting the development of LIDAR systems with our diffuse reflectance targets for many years. Labsphere’s more compact Spectralon® diffuse reflectance targets are commonly used by the military for testing laser rangefinders. The accurately calibrated spectral reflectance coupled with the near Lambertian (diffuse) reflectance means that for those applications you have an accurate, repeatable target to test your system in the laboratory or in the field.

LIDAR systems that are used in larger scale mapping or in autonomous vehicle applications require a larger target area. As the majority of natural objects reflect light diffusely, Labsphere’s diffuse reflectance materials are a natural choice to provide a repeatable simulation for quality assurance, field testing and comparative measurements. Labsphere developed Permaflect Targets to meet the need for a large area, durable and optically stable target material. The large target size, up to 1.2m x 2.4m as standard, coupled with the calibrated spectral reflectance data allows for precision measurement of LIDAR range. Larger targets are needed to reflect a representative number of points across the target over long range test distances of 100m, 200m, 300m and more.

Permaflect is a spray coating which allows it to be applied to large areas or 3D shapes, which allows it to simulate real world objects. Few real-world objects are flat like a target panel, so Permaflect coated objects allow for a repeatable near-Lambertian reflectance levels that can be applied, for example, to a mannequin to simulate a pedestrian.

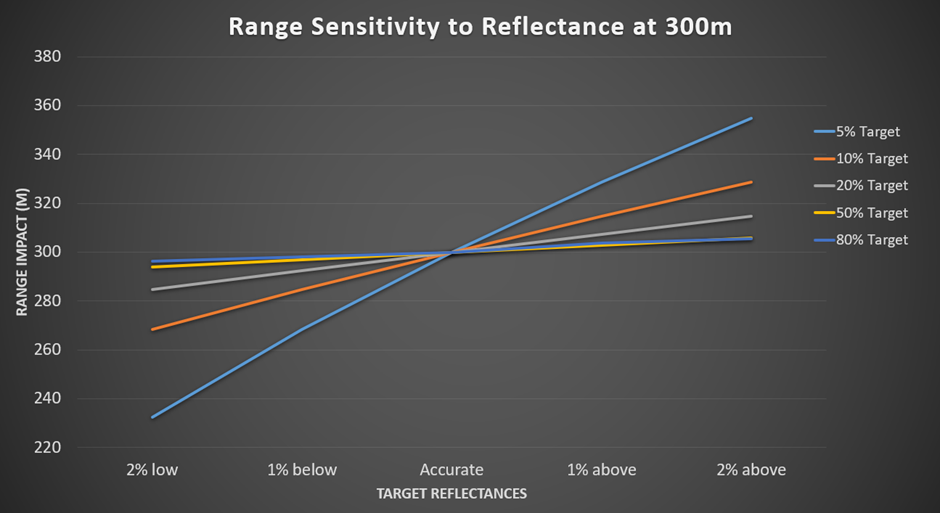

LIDAR targets are commonly deployed outdoors, so some drift in the calibrated reflectance values can be expected over time as the surface is exposed to the atmosphere. Labsphere’s diffuse reflectance materials can to a great extent be cleaned. To counter any residual drop in reflectance, one may employ a calibrated reflectance meter (“reflectometer”) that measures the target reflectance in-situ and allows for any change in the IR reflectance to be considered. A change in target reflectance will directly affect the measured range. The chart below shows the effect on measured range with a change in reflectance for a range of different target reflectance levels. A small change in reflectance has a large effect on the measured range for lower reflectance targets. For example, if the reflectance of a 5% target were to reduce to 4% the measured range at 300 m would measure short by more than 30 m. The only way to know this has happened would be to measure the reflectance of the target and then correct your calculations to this adjustment.

Modelled sensitivity of range measurements to object reflectance at 300nm

Labsphere’s LIDAR Reflectometer Kit was developed to serve this requirement. This handheld reflectometer measures the 8°/hemispherical reflectance at one of three wavelengths (using an interchangeable 850nm, 905nm or 1550nm LED). Watch a short video from Labsphere’s video library. This can be used for verifying the reflectance of a Permaflect target or any other object you wish test the LIDAR system against.