September 14, 2022

The Technical Situation

Certain materials’ testing procedures require putting a sample under extreme conditions or great stress to simulate any situation the material might be in. Exposing a material to high amounts of UV light for a short period can represent the effects of prolonged exposure to the sun. Labsphere was asked for a system that can subject numerous samples to tension and extreme UV irradiance within a controlled environment.

The Challenges, and Labsphere’s Solution

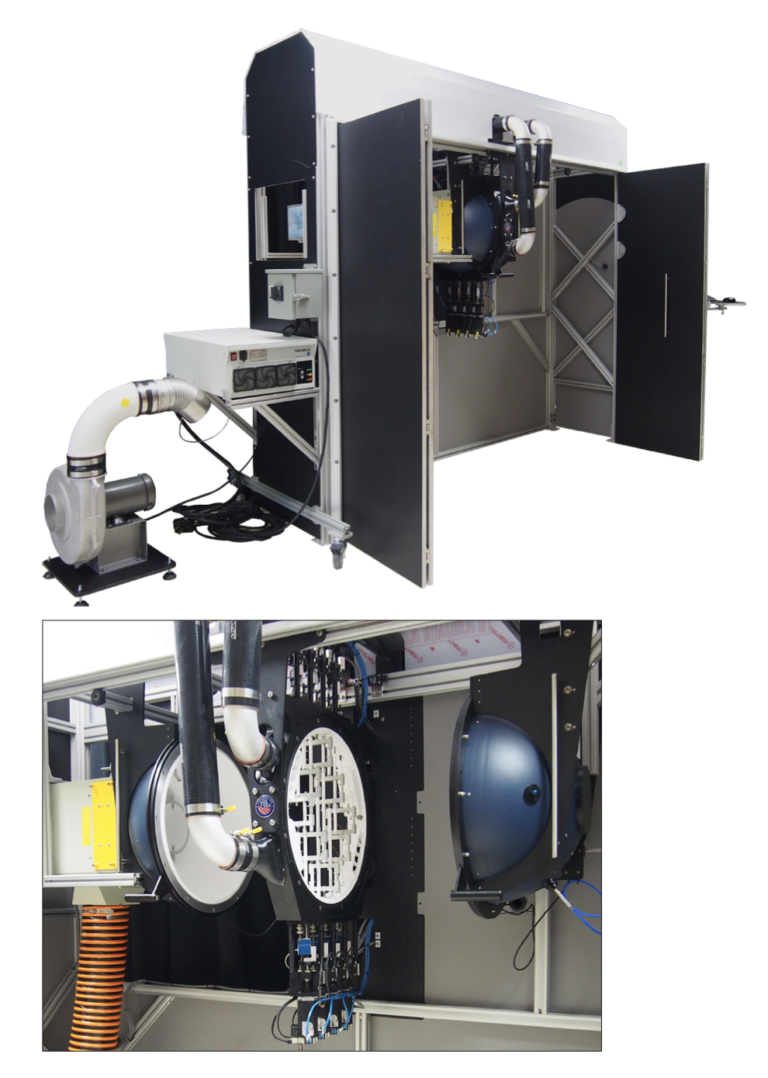

Incorporating a tensile testing system into an integrating sphere environment requires a delicate reworking of the standard geometry. The sphere was built in the shape of a pill, with two hemispheres and a cylindrical tensile testing assembly between them. With careful baffling and other unique features, the system still guarantees reliable test results:

- Eight sample holders each with individual load cell assemblies

- Rollers on each hemisphere for easy exchange of samples between tests

- UV light source capable of outputting irradiance equivalent to thirteen sun and continuously adjusting down to 20% of its full power

- Industrial blower and duct to prevent the light source from overheating

- Environmental control unit for setting the temperature within the sphere

- Sensors installed across the system for measuring oxygen levels, temperature, humidity, and irradiance within the sphere, and tension in each cell

- Custom software optimized for this application and system

The Results

- Multiple safety features ensure that no accidental exposure to the UV rays or extreme temperatures occur during or after testing

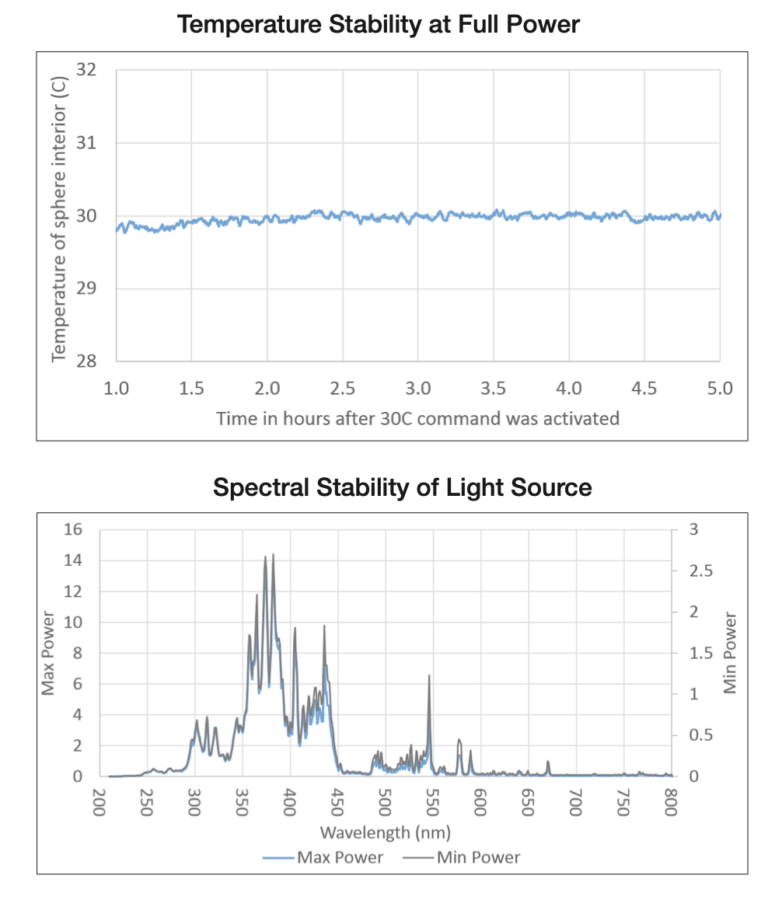

- The light source amply provides enough spectral radiance to meet the client’s specifications, and its continuous adjustability makes a variety of testing environments possible

- Temperature control is accurate and stable, with only ±2°C between samples and ±.2°C overall temperature over four hours

- With eight sample holders, the testing process is highly efficient

- The software provides active monitoring of every sensor and individual control over each load cell, including sinusoidal and pull-hold-relax functions.

- The oxygen and humidity sensors provide additional information on the testing environment and give the client the option to incorporate oxygen and humidity controlling units in the future

- Full test reports were provided, including temperature control, software operation, load cell control, and irradiance calibration and stability